Our Products

Raising the game.

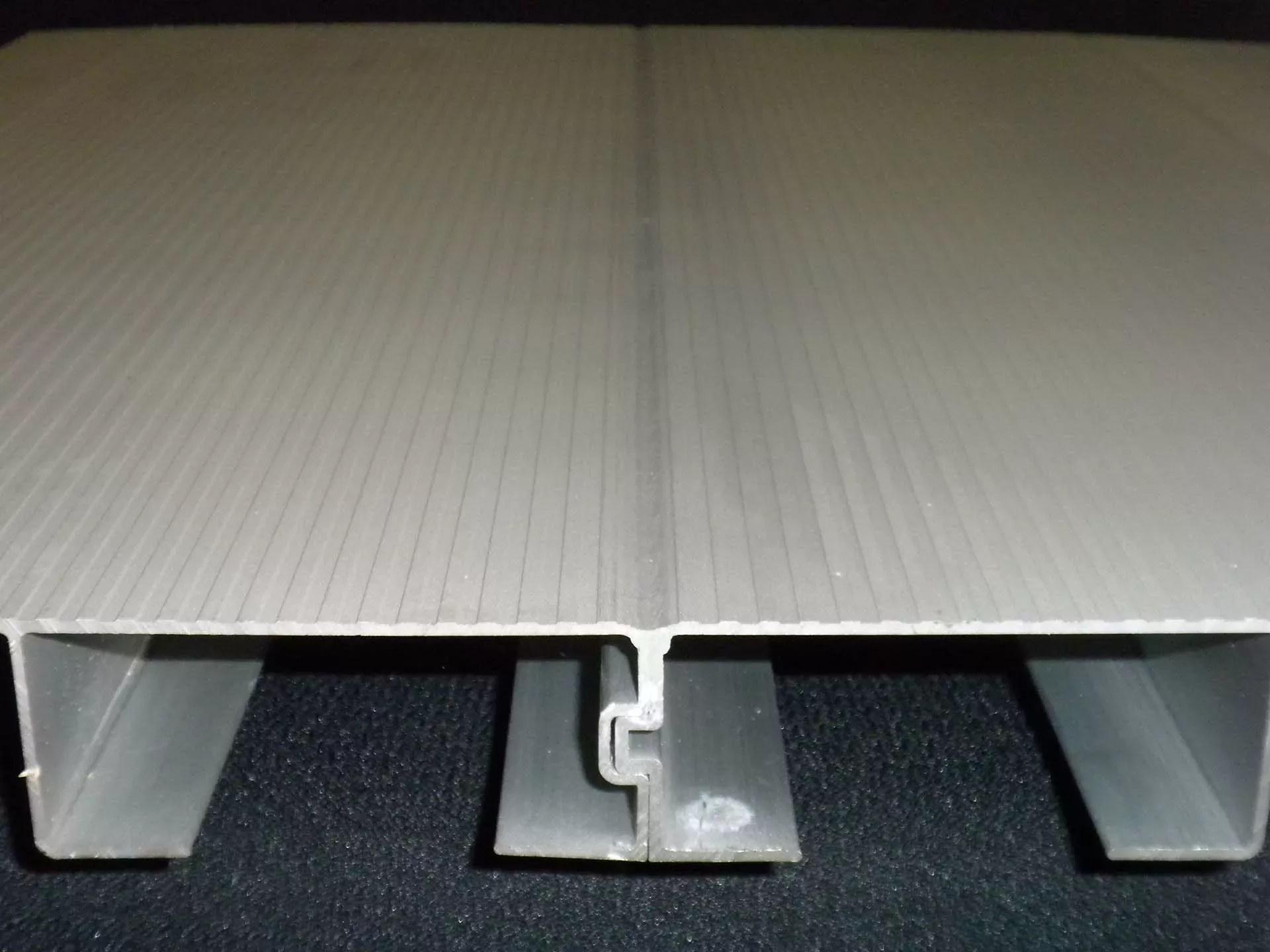

Complete a new construction or enhance a renovation project with a customized system. From design and fabrication to manufacturing and final installation – Dant Clayton meets the full range of project needs.

View Products